A Day on the Farm

GreenWave’s nursery, two farms, and processing facility attract a steady stream of farmers and other partners. Most folks don’t have the opportunity to visit, so we wanted to share a typical day on the water with our farm and nursery team.

After the last few weeks of big weather, it’s nice to have a day that’s flat calm.

Tools of the Trade

The farm team uses a larger vessel for setting anchors and harvest, but for seeding and maintenance, they run skiffs—small, open boats that are easily maneuverable for daily farm chores.

Today Ben Kelsey and Maggie Aydlett are heading out to take kelp samples and tension loose lines to ensure the kelp is getting the right mix of sunlight and nutrients. Ben and Maggie bring essential tools of the trade, ranging from splicing fids to block and tackle to help them complete their tasks.

Surveying the Farm

It’s a short run out to the grounds. As they approach the site, Ben and Maggie do a quick scan to see if any kelp lines are slack or navigation buoys have shifted in a big blow.

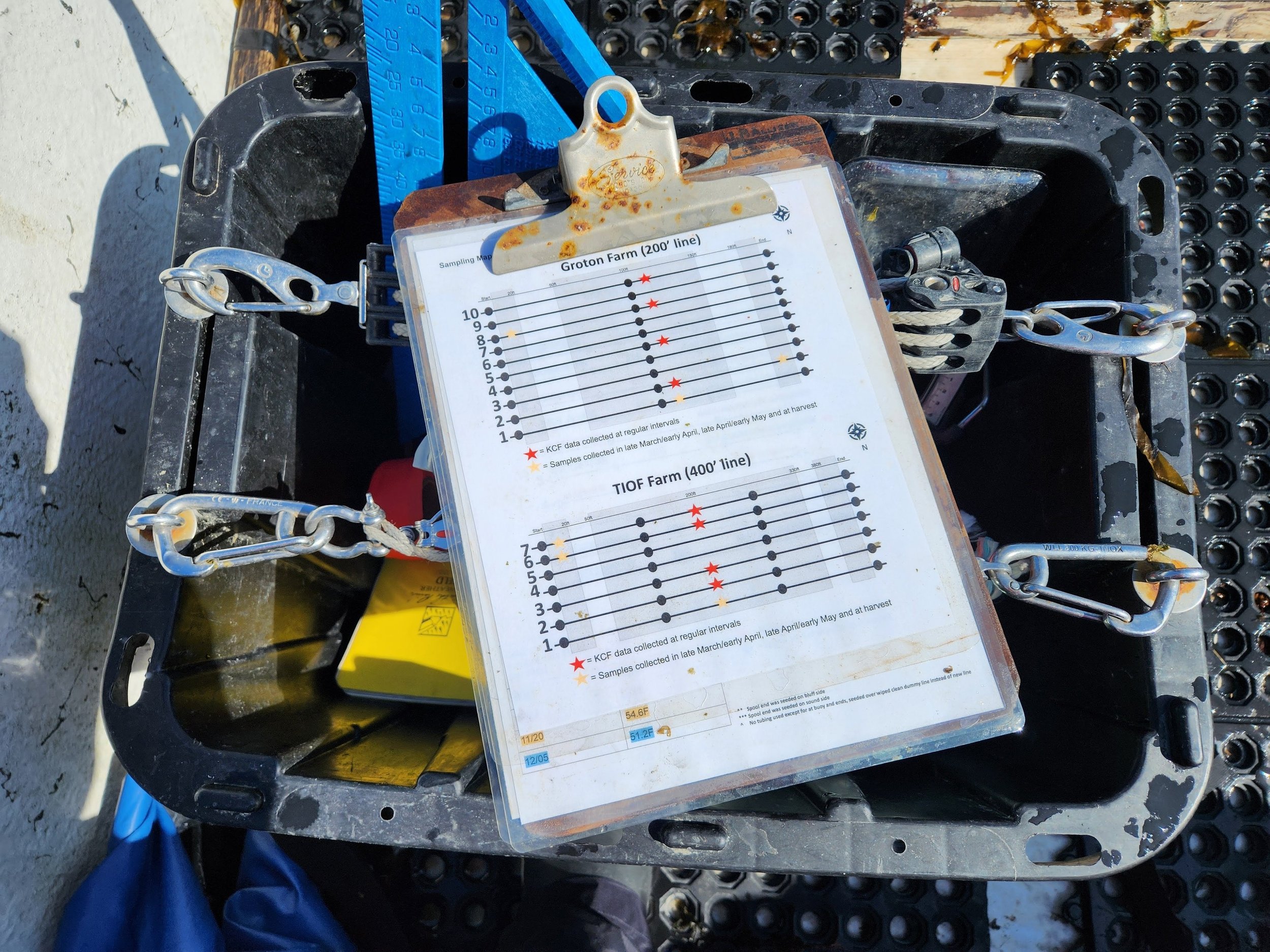

The kelp lines are organized in rows. They use a crop map with planting dates, seed source, and temperatures to orient themselves while they are on the water.

Tracking Growth Rates and Quality

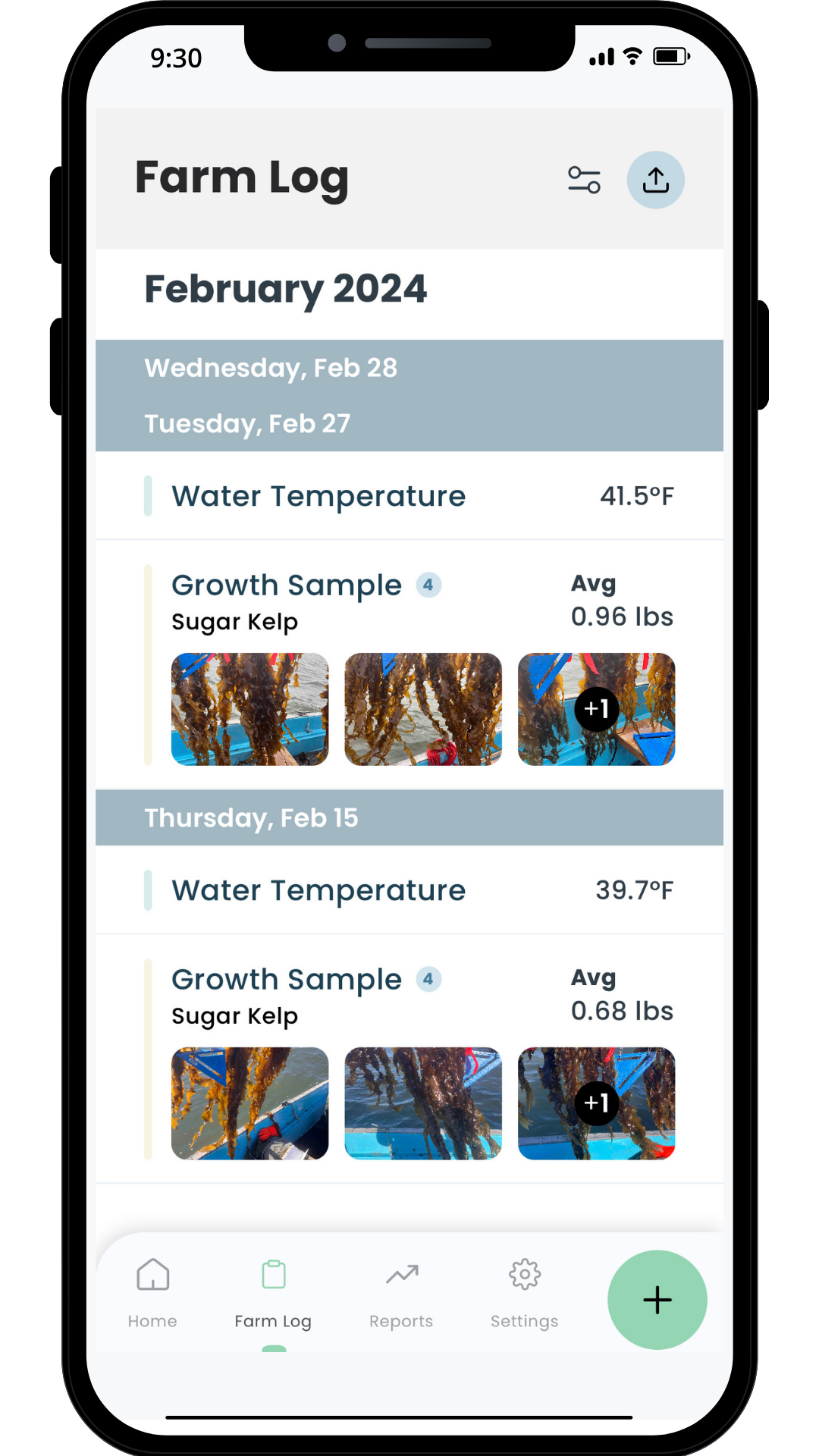

Ben and Maggie pull up the first kelp line to track growth, yield, and quality. They measure water temperature, weight, and blade length, and they also take a water sample to measure nutrient levels. The kelp's holdfasts—the root-like structures of the plant that attach to the grow lines—are thick and strong this year, which is essential for the crop to survive storms that blow through. It’s calm today, but some days, swells as high as 10 feet will roll through the farm.

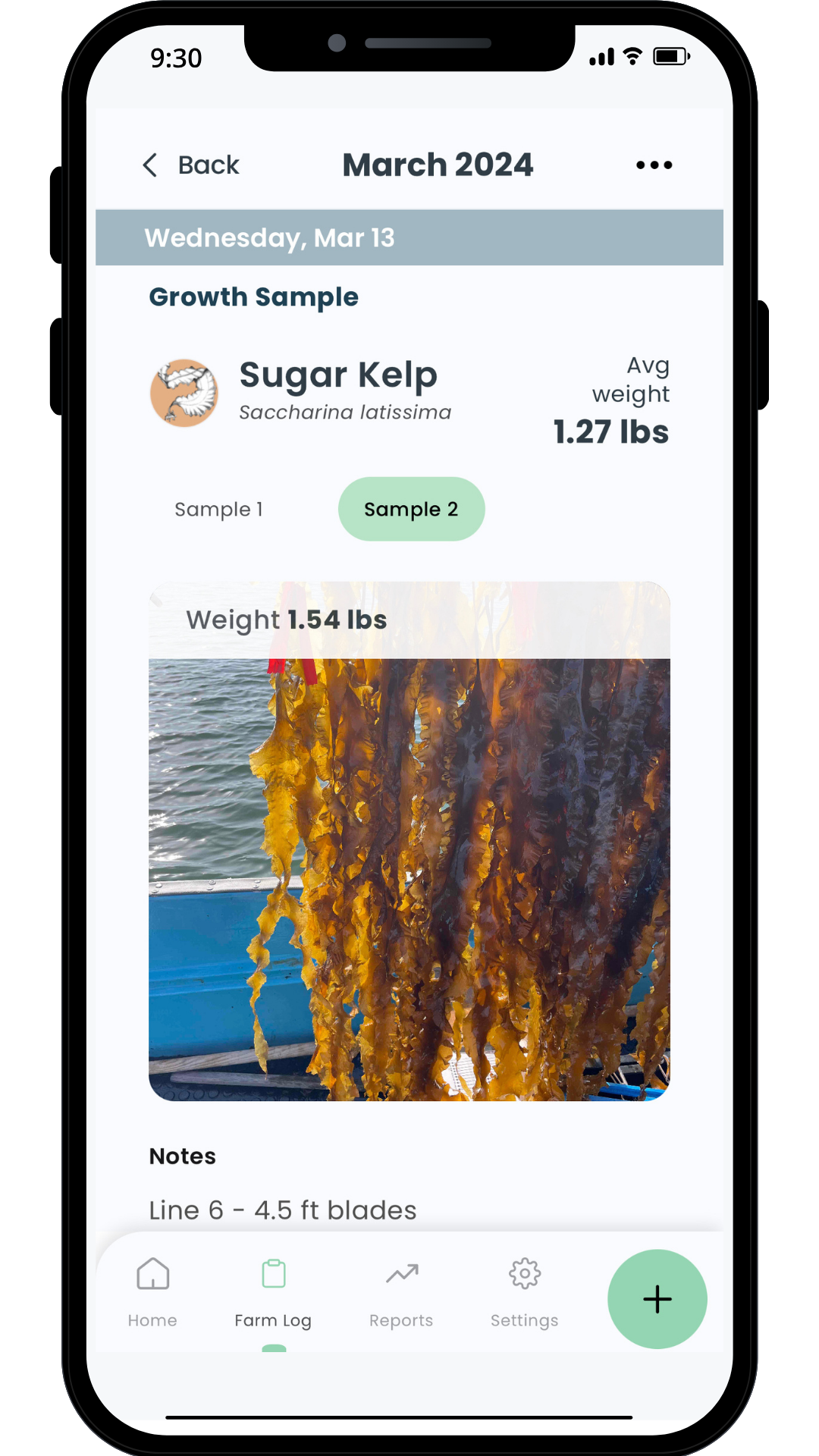

Farmer-Forward Data

Just like the 49 other farmers participating in the Kelp Climate Fund, Maggie logs water temperature and weight measurements in the My Kelp app. GreenWave uses this data to monitor crop growth throughout the season and make year-to-year comparisons.

Walking the Lines

While Ben and Maggie are taking samples, they “walk the lines,” moving along each line of kelp to check for any twisted buoys, sagging or detached seedstring, or tangled lines.

Here, Ben splices detached seedstring from line 5 back onto the growline to prevent line loss.

Collecting Sorus

In order for sorus to develop, the kelp blades need to be mature. Seeing sorus tissue this early in the season is a good sign. Maggie finds ample sorus tissue on lines 2, 6, and 9, and will take it back to the GreenWave headquarters to build up seed supply for next season.

Ben and Maggie also check for any sorus tissue so that they can replenish GreenWave’s seed bank.

Sorus tissue can be identified by the dark chocolate brown stripe down the center of the kelp blade which holds the spores necessary for reproduction.

Growing a Blue Thumb

The farm team compares growth rates between different lines. With the help of partners and Maggie’s blue thumb, we’re now able to plant at optimum temperatures and nutrient conditions. Outplanted on Halloween, lines 5, 7, 9, and 10 are seeing much stronger growth compared to lines 1 and 2, which we outplanted in December.

A Farmer’s Work Never Ends

After checking each line, Ben and Maggie head back to the docks. The kelp is growing great this year, and the farm team is already thinking about what’s next on the list. They have to get ready for what looks to be a big harvest and set up the machinery at GreenWave’s new processing hub.