The Future of Seed Production Is Local—and Fits Inside a Box

Seed is one of the most important variables in farm profitability, both as an expense and its potential impact on yield. Quality seed is the foundation for a successful season; poor seed quality can upend productivity and a farmer’s bottom line. GreenWave is taking the guesswork out of seed production, developing tools like a nursery-in-a-box—a modular, shippable system built to deliver reliable, high-quality seed at lower cost.

“If farmers are going to make a living, they need seed they can count on,” says Toby Sheppard Bloch, GreenWave’s Director of Infrastructure.

GreenWave has spent nearly a decade developing and redesigning nursery systems to make seed production reliable, affordable, and timely for regenerative ocean farmers—testing new designs, iterating on infrastructure, and sharing findings so operators everywhere can replicate proven approaches.

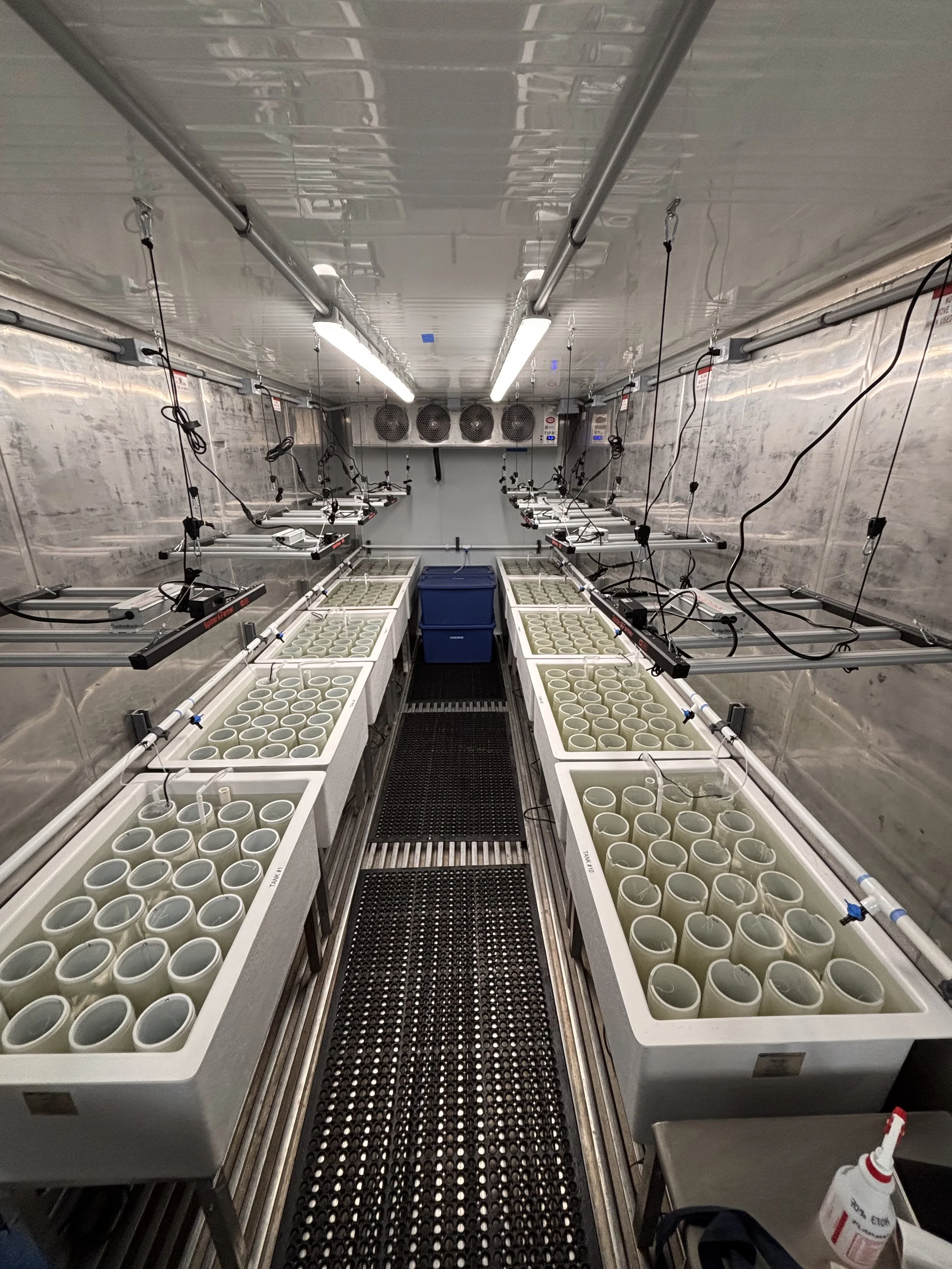

In 2021, GreenWave partnered with Hortimare, a global leader in kelp seed production, to optimize and modernize our New Haven nursery, upgrading the facility to strengthen quality controls, reduce contamination risks, and increase production efficiency and cost. The result was a modular, 20-foot refrigerated shipping container system that produces twice the amount of seed using less than half the labor and a third of the space of our original facility.

Those improvements paid off. GreenWave’s farm production tripled, and the nursery has achieved a 100% seed spool success rate since 2023.

This design became the foundation for “nursery-in-a-box”—a standardized system built to help communities reduce costs, control their seed supply, and establish their own regional nurseries with minimal trial and error. This summer, GreenWave fabricated the first nursery-in-a-box in Massachusetts and shipped it to Alaska as a turnkey system, ready for on-site assembly and seed production.

“This model is a way for GreenWave to crystallize the expertise we’ve developed while building several seed production facilities, replicate consistent seed quality, and reduce friction for new nursery operators,” says Toby. “They can start with something validated without spending weeks troubleshooting.”

And while the container system standardizes the infrastructure, GreenWave’s Kelp Nursery Operations Manual standardizes the techniques. Together, they form a field-tested playbook that pairs proven hardware with step-by-step protocols to ensure operators have the tools and the know-how to deliver consistent, high-quality seed in their region.

“Operators were spending a lot of time worrying about the infrastructure and less on the actual protocols,” says Dave Bailey, GreenWave’s Director of Farmer Advancement. “We wanted to make a system that’s really simple and user-friendly, so operators can focus on producing quality seed.”

When kelp producers in Kodiak, Alaska approached GreenWave in spring 2025 seeking reliable seed for their farms, the team got to work. Over the course of three months, staff fabricated a nursery inside a 40-foot shipping container—doubling the size of GreenWave’s original 20-foot model to accommodate the water filtration and processing systems inside the container. The team shipped the finished nursery, which included environmental controls, filtration systems, and efficient lighting, to Alaska in August.

Before it arrived, Allie Conrad, the nursery’s new operator, trained with GreenWave’s seed production team in New Haven. In Kodiak, the project is being hosted in partnership with Alaska Sea Grant, which is providing a home base for the facility outside the Kodiak Seafood and Marine Science Center. Once the container landed in Kodiak, GreenWave traveled north to bring the system online. By early October, Allie began propagating the first batch of seed.

GreenWave will operate the Kodiak nursery while tracking the full costs of running it, from power and supplies to labor, to create a transparent financial model for the farmers in Kodiak who have now started a co-op.

“This model allows a group of producers who may not have significant landside infrastructure to own and control their own seed production, rather than depending on third parties for this critical piece of the value chain,” says Toby.

As the seaweed industry grows, consistency in seed production is essential. Standardized nursery systems help farmers compare results, share discoveries, and troubleshoot problems across regions.

“When everyone’s working from a similar platform, learnings can be shared across nurseries,” says Toby. “If an operator discovers a better piece of equipment or a design improvement, everyone can quickly incorporate that change without having to reverse-engineer how it was developed.”

With interest already coming in from other coastal communities, GreenWave’s nursery-in-a-box aims to make that reliability achievable, bringing seed production closer to the water, lowering barriers to entry, and giving farmers a tangible solution to grow their own future.

Explore a 3D model of GreenWave’s nursery-in-a-box layout on the Ocean Farming Hub.